| We've started sourcing parts! Rings

supplied and modified by Total Seal, wrist pins from Venolia. Our

piston order with Ross Racing Pistons has been finalized and should

be ready soon.

Conrods will be supplied by Carrillo. It will take about a month

for them to finish the rods. The Carrillo tech confirms that the

hemi rod bearing and wristpin sizes will be more than sufficient

to handle the expected horsepower.

Pistons have arrived from Ross. They look great and are even lighter

than expected. We had Ross lighten them internally with extra

milling. At 1140g they are about three times heavier than normal V8

or harley pistons but the rods, rod bolts and bearings will be up to

the job. With this weight of piston, max rpm of 6000 should be safe.

For a production version of the piston

a new forging blank could be made. This would allow for an improved,

lighter piston, a narrower, lighter conrod small end, and a

shorter, lighter wrist pin, allowing a higher rpm limit, possibly

close to 7000. The current piston design will be fine for

the purpose of testing the prototype motors.

Received the conrods from Carrillo. Pistons and pins fit

properly. Nice work!

Now the 3D CAD model of the crank can be adjusted so that the rods

have the correct side clearance.

The crankshaft will be the next part to be machined.

Crankshaft designing, modeling, and virtual balancing nearly

completed. Many thanks to Graham Martin of Napier, New Zealand,

for tons of advice and information on cranks old and new!

Marine Crankshaft is able to do everything required in-house, including

machining, smoothing and detailing, heat treating, grinding, shot

peening and plasma nitriding. Their other

cranks look great and we are confident that we are going to

get an excellent product from them. Each 7" diameter 4340

steel crank billet weighs about 150 lb to start and , when machined to final

size, will weigh about 25 lb. Each counterweight will weigh from

10 to11 pounds, depending on the balance factor. The

counterweight design can be finalized after the cranks arrive. , when machined to final

size, will weigh about 25 lb. Each counterweight will weigh from

10 to11 pounds, depending on the balance factor. The

counterweight design can be finalized after the cranks arrive.

While waiting for the cranks to show up, cylinder liners and cylinder head/cylinder sealing

rings can be ordered. The liners, from LA Sleeve, will be iron, 0.150" wall

thickness, and flanged on top to provide enough room for a sealing

ring groove. This sealing ring, from Garlock Helicoflex, is tough

enough to take the place of a head gasket. It's a hollow metal

ring with enough internal pressure to seal against combustion

gases after it is squeezed a precise amount as the head is torqued

to the cylinder. internal pressure to seal against combustion

gases after it is squeezed a precise amount as the head is torqued

to the cylinder.

Received liners from LA Sleeve. O-ring grooves will

be cut after they are pressed into the aluminum cylinders. They

look good!

Crankshafts

arrived from Marine Crankshaft and look beautiful! They did a top-notch

job on radius blending and smoothing. Excellent work! Now the CAD model

of the cranks can be changed to match the real cranks as closely as

possible. Next, the virtual balancing of the cranks can be accurately completed (using the Alibre

Design Motion Module) by changing the models of the counterweights so

that they are a little bit heavier than they need to be, to allow for

balance hole drilling in the real counterweights.

Counterweights

have been fabricated by a local machine shop, Foreman CNC, and are

nicely finished and as specified. All the major bottom end parts

are completed. The crank and counterweight assembly is ready to be

sent out for balancing. Counterweights

have been fabricated by a local machine shop, Foreman CNC, and are

nicely finished and as specified. All the major bottom end parts

are completed. The crank and counterweight assembly is ready to be

sent out for balancing.

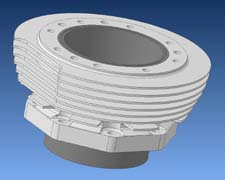

Next up will be cylinders made from 6061-T6.

go to page 2 3

|