Crank was

successfully balanced by a local machine shop, J.B.Precision, to a

balance factor of 50%. The computer model of the crank and

counterweights turned out to be pretty accurate because the shop didn't

have to remove too much metal to get the balance just right. The crank will be re-balanced to 60% with

the larger counterweights attached. This will make it easy to evaluate

two different balance factors when the motor is ready to run.

Counterweights can be unbolted and removed through the sump without any

other motor disassembly.

get the balance just right. The crank will be re-balanced to 60% with

the larger counterweights attached. This will make it easy to evaluate

two different balance factors when the motor is ready to run.

Counterweights can be unbolted and removed through the sump without any

other motor disassembly.

Still

waiting for quotes for the cylinder machining so onward to sump and oil

pump design! Bill Dailey at Dailey Engineering is making a pump for the

motor and has been very helpful with info on dry sump oiling system

layout. Still

waiting for quotes for the cylinder machining so onward to sump and oil

pump design! Bill Dailey at Dailey Engineering is making a pump for the

motor and has been very helpful with info on dry sump oiling system

layout.

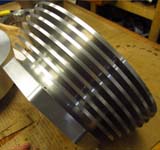

Received oil

pump from Dailey Engineering and it's a very beautiful piece

of machining and engineering!

Finally made a decision on the cylinder machining!

Foreman CNC is going to make two front and two rear cylinders. There

aren't too many local machine shops that can turn something this big on

their CNC lathes. Here

are a few images of the first machining operations for the cylinders.

A test rig for evaluating trigger

wheels and sensors is finished. The sensor signal can be viewed on an

oscilloscope at different crank speeds and wheel-to-sensor air gaps. It

is important to have a good, sharp series of pulses at cranking speed

and at maximum RPM. Here are some images of traces

recorded at several different motor speeds. A test rig for evaluating trigger

wheels and sensors is finished. The sensor signal can be viewed on an

oscilloscope at different crank speeds and wheel-to-sensor air gaps. It

is important to have a good, sharp series of pulses at cranking speed

and at maximum RPM. Here are some images of traces

recorded at several different motor speeds.

Once the crank trigger wheel and

sensor are sorted out we will be ready to see about

getting some cases made! out we will be ready to see about

getting some cases made!

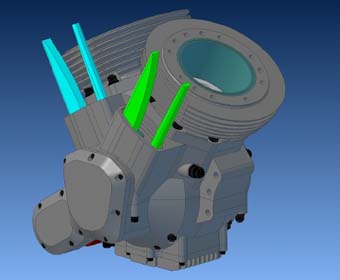

The upper and lower case design mods

are nearly finished. Most of the changes have been done to make the

machining easier. The attached 3d pdf shows most of the latest design

updates.

Not much progress over the last few

months. Still fiddling with final details on the case designs. Changes

were required to incorporate the chosen cam gears and chains. For the

prototypes, chains, gears, guides and tensioners from a Ford 4.6l

modular motor (recent Mustangs) will be used. The chains

should be strong enough for our application and after-market

accessories like adjustable cam sprockets are easily found.

Spiralock taps will be used to cut

all the fastener threads in the cases. These taps have a special shape

that helps to keep the studs and fasteners from loosening with

vibration and thermal cycling. Threading and evaluating test pieces of

aluminum is underway.

All the fastener lengths and sizes

are sorted out. ARP studs, nuts and bolts will be used.

The front lower cam drive is shown

in the picture, featuring both an adjustable cam sprocket and crank

sprocket. The upper cam drive details are still not nailed down but

case machining ahould be started soon.

All the cam drive sprockets,

link-belts and roller chains have been finalized and sourced from

Cloyes Gear and Products. Their tech services department was helpful in

finding chains with the right pitch and number of links. Thanks Mike!

New models of the cylinder head are

almost completed. The first version would have been very difficult to

machine. The current version has a number of changes to simplify

machining, plus two more parts. Updated 3D pdf to come soon!

Bill is concentrating on learning

more about CAM programming. After talking to

a number of CNC machine shops it seems like a good idea to re-do the

CAD models of the upper and lower cases to make them easier and less

expensive to machine. By working out the actual toolpaths and times

required to make the parts the model shapes can be optimized so that it

might be possible to machine them more quickly and to use a 4-axis

Vertical Machining Centre instead of a 5-axis VMC.

Meanwhile, Foreman CNC has been able

to find some time to move ahead with the cylinder machining!

go to page 1

3

|